Contact Kulzer International

Stress-free digital dentures with 3D printing.

dima Print Digital Denture helps you create duplicate dentures in a fast, easy process and serve a new market for back-up (e.g. for travel or emergencies) dentures.

Benefits

More time for other things

- Fast production time and less stress: produce a fully 3D printed denture in just under 2 hours!

- Easy to learn: 3D fabrication process is easy to learn and hand off among colleagues

- For cara printer users: use a known and secure process to fabricate a fully digital denture with minimal effort

- Less stress and time pressure: more time to repair a broken denture since the patient has a duplicate denture as back-up

Higher profitability

- A fast and cost-effective digital solution to produce Try-ins and full dentures, e.g. as back-up or travel dentures

- Total material cost for fully 3D printed denture approx. €10.81 for upper and €12.45 for lower arch

- Exceptionally precise results with 3D printed dentures

- Gain new dentist customers by offering a new profitable business area

Good to know

Indications

With dima Print Digital Denture, technicians can fully produce a good quality back-up denture using the fast and secure cara 3D printing workflow. The digital denture solution consists of three class IIa materials: dima Print Denture Base Try-in for the production of Try-ins, as well as dima Print Denture Teeth and dima Print Denture Base for the production of high quality duplicate dentures with multiple shade options.

- Try-ins

- Travel/back-up dentures

- Immediate full dentures

- Permanent full dentures

Applications

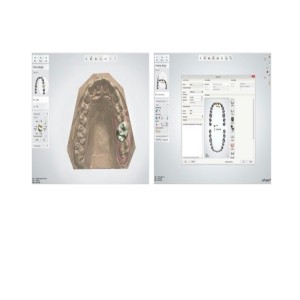

Workflow

Copy-Denture Workflow

References

„…the materials and system improve both the workflow and the treatment process for patients. Users can make the design and printed denture by themselves and everyone can use the system thanks to its easy operation.” - Dr. Fumiaki Yamazaki, Imizu City, Toyama Prefecture, Japan

Dr. Fumiaki Yamazaki established the Yamazaki Dental Clinic in 2002 in Imizu City, Toyama Prefecture, Japan. He travels extensively as a trainer and lecturer and is a member of the Japan Plate Denture Association. In 2013, his PhD dissertation was awarded as the best dissertation by the Academy of Clinical Dentistry

Specifications

dima Print Denture Base

| MDD class | Color | Flexural Strength (Mpa) | Flexual Modulus (Mpa) |

Cleaning time in isopropanol cara Print Clean |

Post-curing time HiLite Power 3D |

Post-Curing time LEDcure (no turning of object necessary) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IIa | Light Reddish Pink, Light Pink, Original Pink, Dark Pink | > 65 | > 2000 |

pre-cleaning: 3 minutes post-cleaning: 2 minutes |

20 minutes (10 minutes front side +10 minutes reverse side) in Glycerin for combined Base&Teeth |

Denture program, cure in Glycerin for the chosen teeth color |

||||||||

Printing performance overview

| Example | Build height [mm] | Time [min] for 50 µm resolution | Time [min] for 100 µm resolution | Material consumption [ml] | Avg. material costs/part [€] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Denture base one upper arch |

1101 | - | 58 | 17.98 | 5.98 | |||||||||

|

Denture base one lower arc |

1189/1108 | - | 56 | 20.09/17.80 | 5.98 | |||||||||

dima Print Denture Teeth

| MDD class | Color | Flexural Strength (Mpa) | Flexual Modulus (Mpa) |

Cleaning time in isopropanol cara Print Clean |

Post-curing time HiLite Power 3D |

Post-Curing time LEDcure (no turning of object necessary) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IIa | A1, A2, A3, A3.5, B1, B2, BL1 | > 50 | > 100 |

pre-cleaning: 3 minutes post-cleaning: 2 minutes |

20 minutes (10 minutes front side +10 minutes reverse side) in Glycerin for combined Base&Teeth |

Denture program, cure in Glycerin for the chosen teeth color |

||||||||

Printing performance overview

| Example | Build height [mm] | Time [min] for 50 µm resolution | Time [min] for 100 µm resolution | Material consumption [ml] | Avg. material costs/part [€] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Denture teeth one upper arch |

1650 | 26 | - | 7.11 | 2.35 | |||||||||

|

Denture Teeth one lower arch |

1650 | 25 | - | 6.82 | 2.35 | |||||||||

dima print Denture Base Try-in

| MDD class | Color | Flexural Strength (Mpa) | Flexual Modulus (Mpa) |

Cleaning time in isopropanol cara Print Clean |

Post-curing time HiLite Power 3D |

Post-Curing time LEDcure (no turning of object necessary) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IIa | White | > 65 | > 2000 |

pre-cleaning: 3 minutes post-cleaning: 2 minutes |

20 minutes (10 minutes front side +10 minutes reverse side) in Glycerin |

Try-in program, cure in Glycerin |

||||||||

Printing performance overview

| Example | Build height [mm] | Time [min] for 50 µm resolution | Time [min] for 100 µm resolution | Material consumption [ml] | Avg. material costs/part [€] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Try-in one upper arch |

1147 | - | 43 | 26.24 | 8.92 | |||||||||

|

Try-in one lower arch |

1130 | - | 42 | 18.20 | 8.92 | |||||||||