Contact Kulzer International

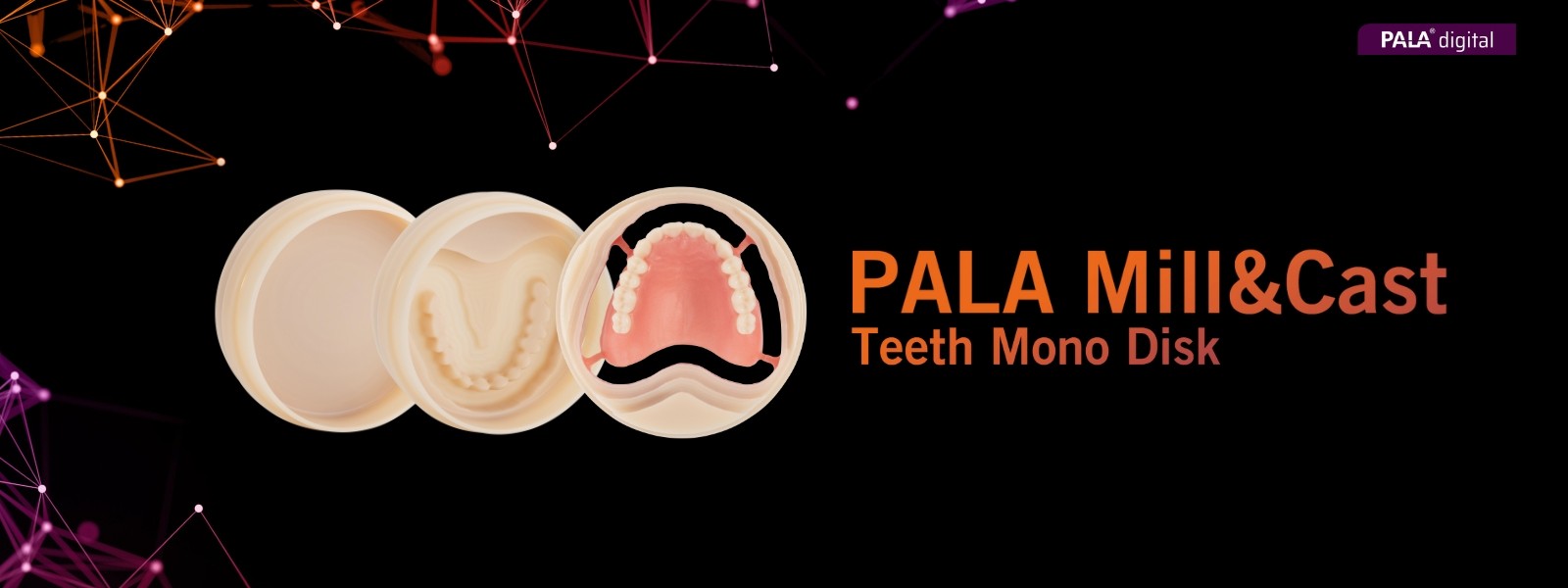

Pala Mill&Cast Teeth Mono disk is suitable for milling full tooth archs to manufacture dentures.

The disk is part of the Pala Mill&Cast Workflow and is used in combination with Kulzer PalaXpress denture acrylic.

With Pala Mill&Cast you enjoy the benefits of precise and efficient denture manufacturing. Our monolithic manufacturing process reduces manual work steps while ensuring a secure bond between the base and dental arch without any bonding. The precise workflow guarantees that only minimal corrections are necessary - efficiency that pays off.

Benefits

| Flexible design |

| Freedom in prosthesis design for the greatest possible application potential for your patients |

| Efficient workflow |

| The hybrid workflow for high-quality full dentures |

| Monolithic denture option |

| For high strength and durability of the denture. |

| No bonding needed |

| Secure bond between base and dental arch without any bonding |

How it works

Take a look at this video, which shows the digital workflow for the fabrication of complete dentures with Pala Mill&Cast and PalaXpress.

Application Guide

| Wich content you can expect: |

| 1. Design of denture and creation of stl-files, using the example of a 3Shape design |

| 2. Preparation of stl-files for transfer to cara Mill CAM 5 software |

| 3. Transfer of stl-files to CAM 5 smart software |

| 4. Milling operation 1: Tooth arch basal |

| 5. Filling procedure with PalaXpress und polymerisation |

| 6. Milling operation 2: Final denture |

| 7. Removal and finishing of denture |

| Application Guide |

Instruction for use

Contact