Contact Kulzer International

HeraCeram cre-active – the aesthetic finishing solution

Creativity meets efficiency: aesthetic ceramic individualisation made easy

HeraCeram cre-active empowers you to achieve lifelike, stunning restorations with ease. Developed in close collaboration with dental technicians, HeraCeram cre-active combines creativity and efficiency, enabling precise individualization of pink and white aesthetics for monolithic zirconia, lithium disilicate, and all HeraCeram veneering ceramics.

Perfect aesthetic results with minimum effort

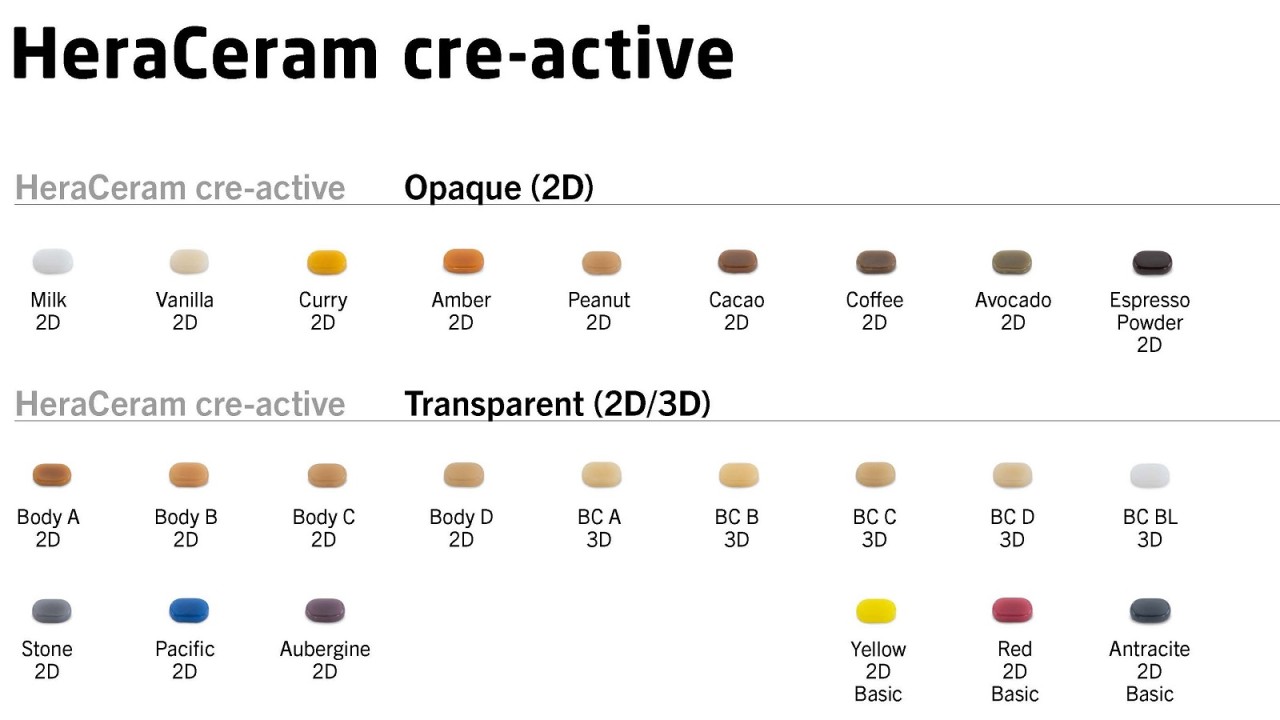

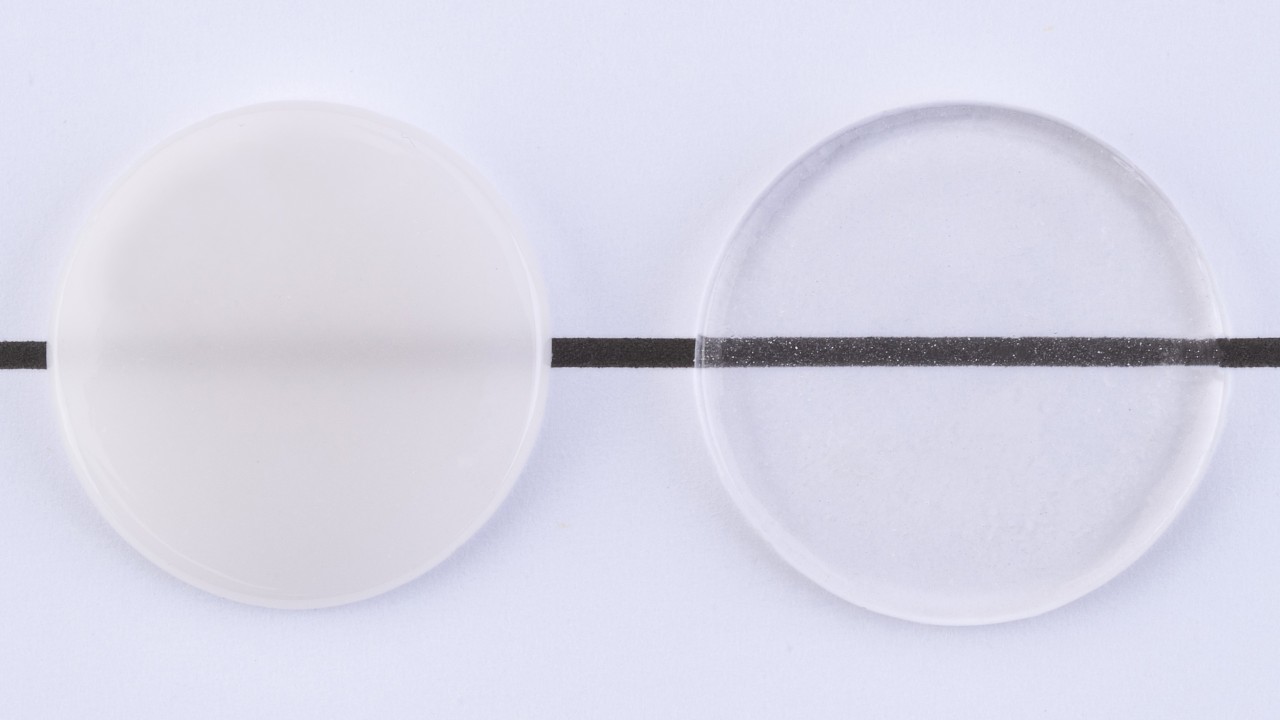

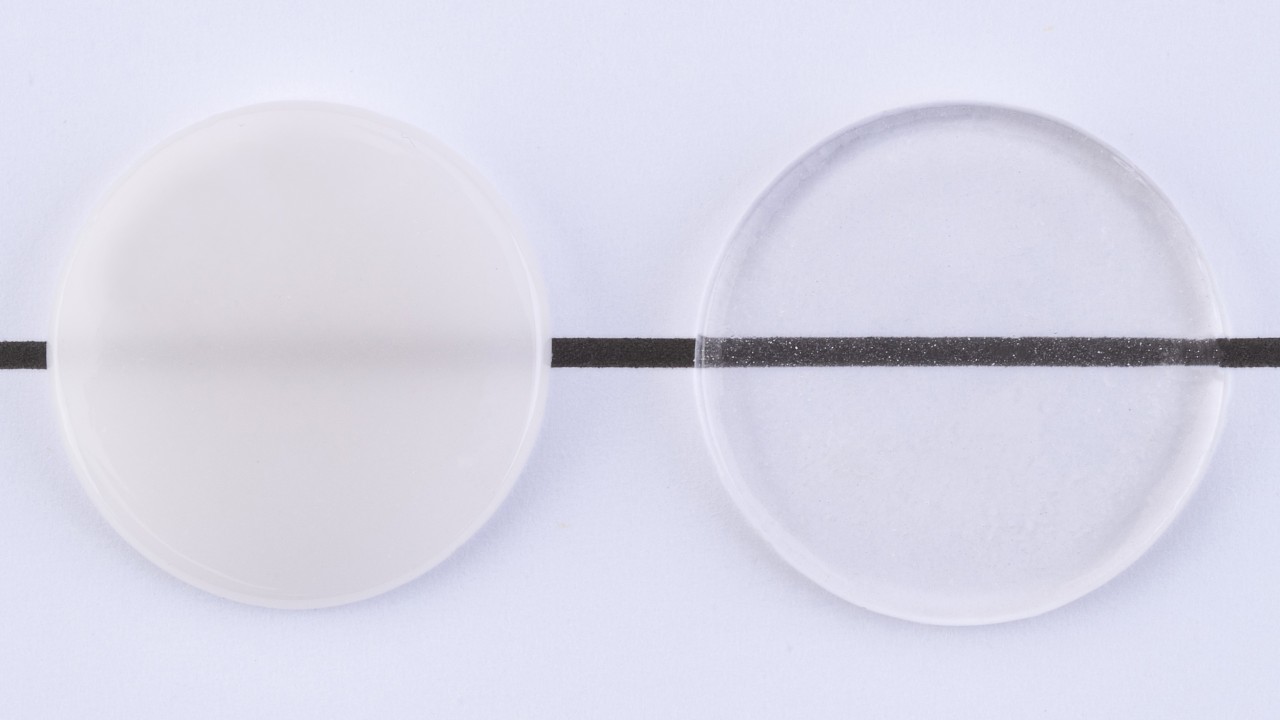

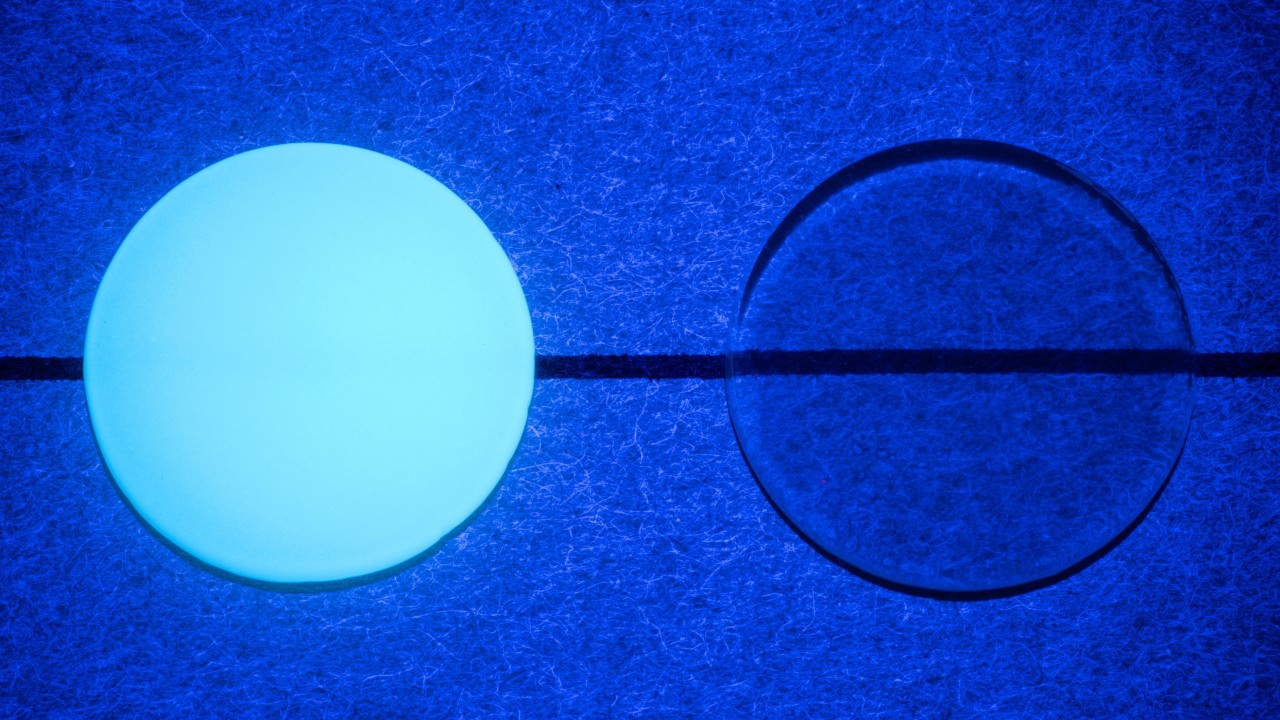

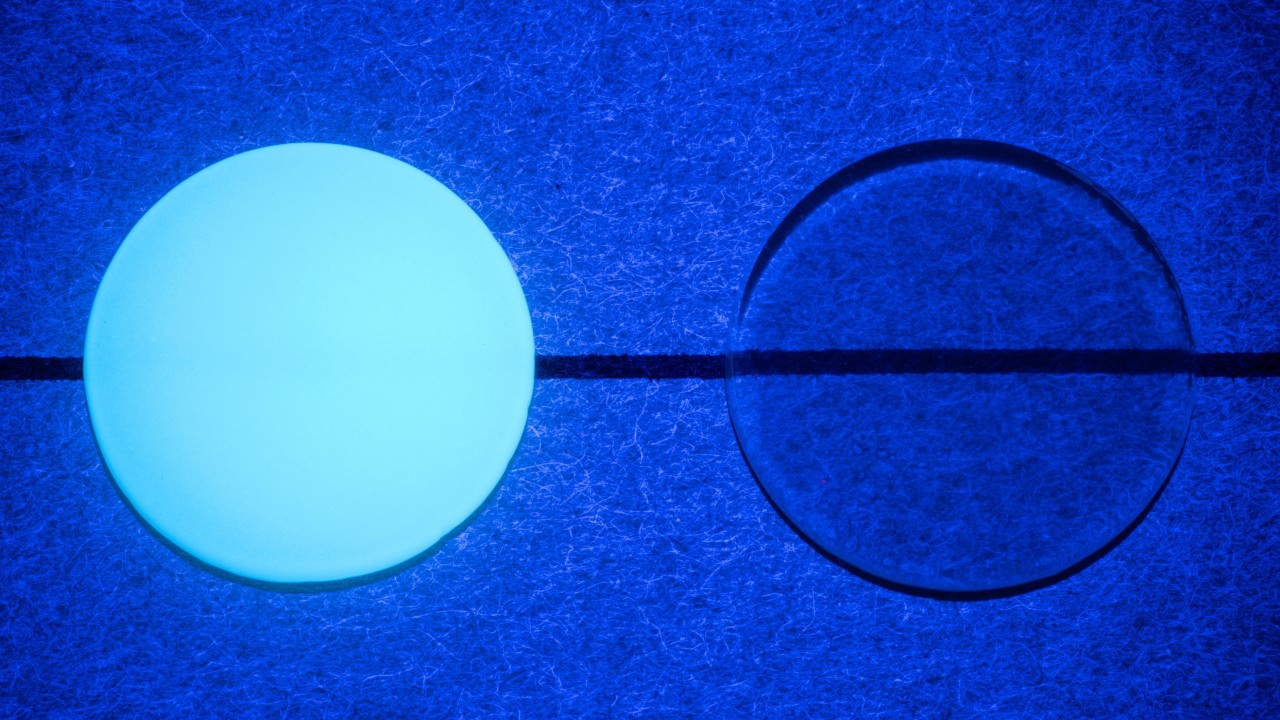

Thanks to high-quality 2D and 3D liquid ceramic components, natural-like light-dynamic appearance, surface structures as well as translucency effects can be created comfortably in an efficient and reproducible way.

HeraCeram cre-active for next level ceramic individualization

Benefits

Technically Perfect

- 2D and 3D liquid ceramic components in different translucency and opacity settings for advanced detailing

- User-friendly consistency and shade stability for convenient, reproducible application (e.g. wet-in-wet application)

- Comparable results before and after firing

Optically Perfect

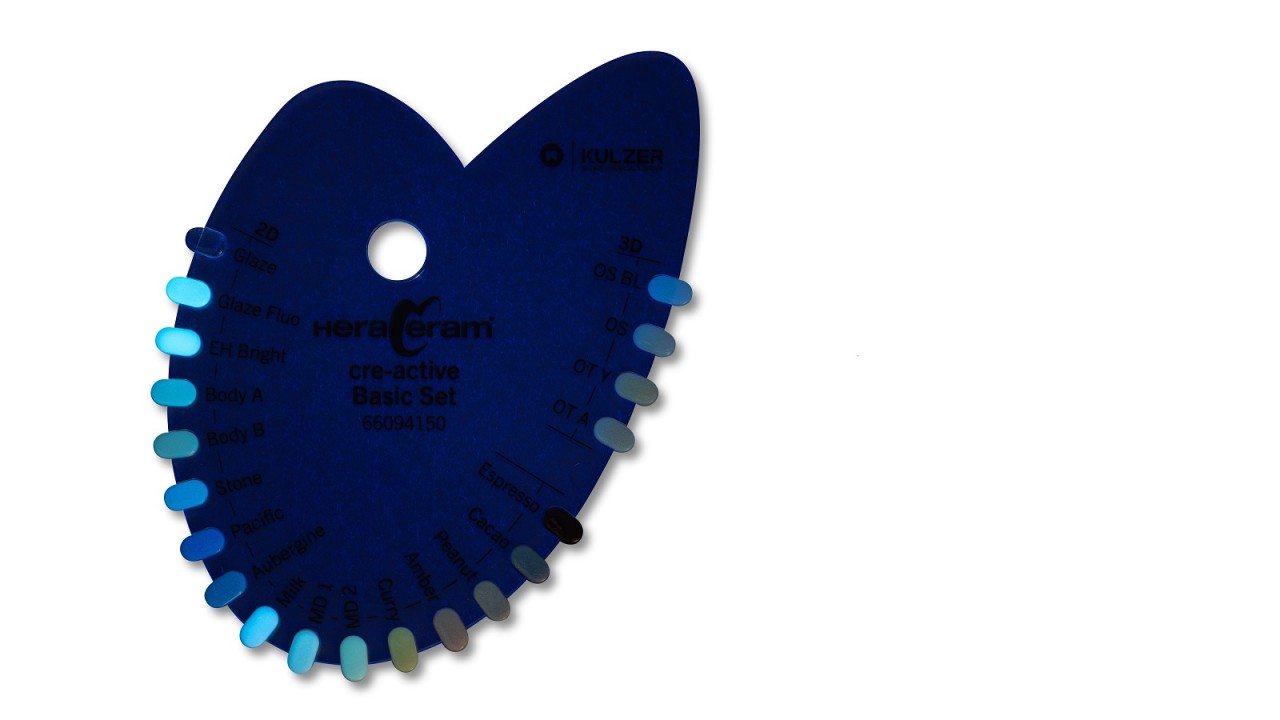

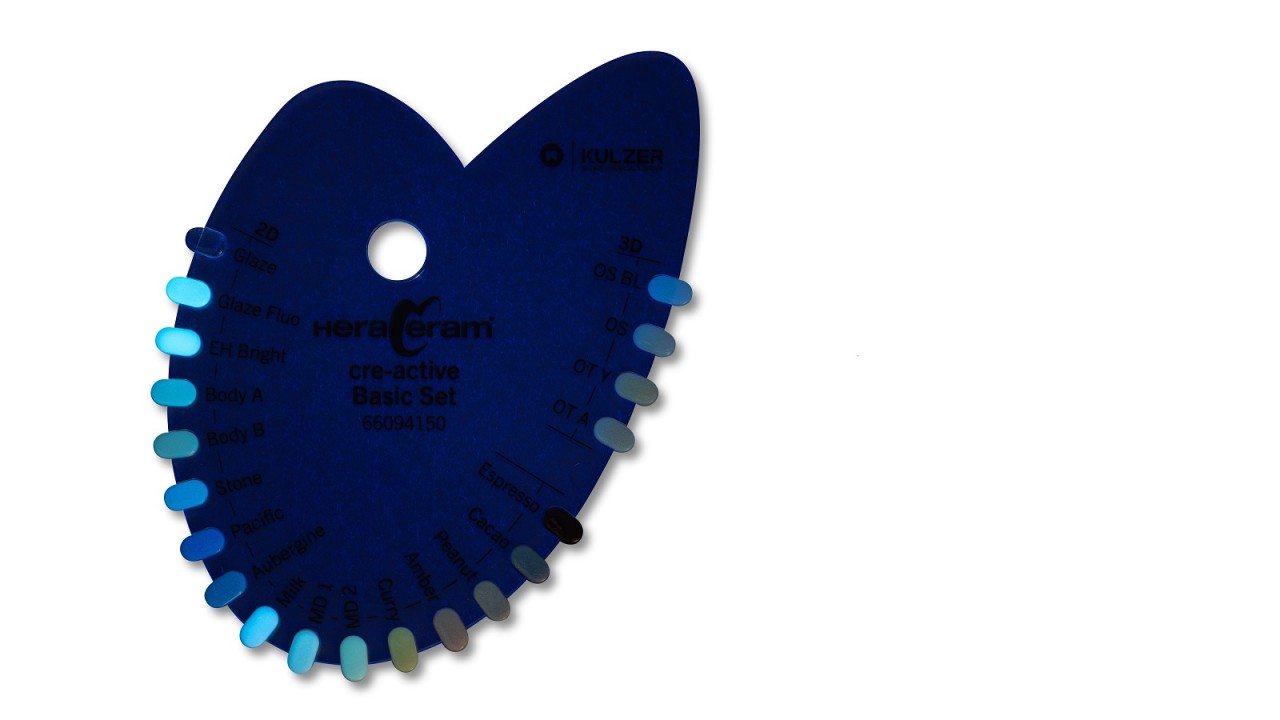

- Create natural light-dynamic effects (fluorescence, opalescence) even in thin layers

- Upgrade the aesthetics of monolithic restorations with lifelike properties for nature-like restorations on the modell as well as in patiens mouth

- Impart depth, translucency and natural surface structures

Simply Perfect

- Versatile design options for pink & white aesthetics

- Covers techniques from standard staining to advanced hybrid micro-layering

- Intuitive integration into the existing HeraCeram product philosophy

Application & Techniques

Explore the user-friendly consistency and effortless processing of cre-active components. Learn step-by-step techniques - from standard staining to high-end hybrid micro-layering. Engaging video tutorials provide valuable insights into key applications.

HeraCeram cre-active in practice

Get exclusive insights from Dental technicians - who have co-developed and tested HeraCeram cre-active already – how HeraCeram cre-active has revolutionized their workflow, enabling them to achieve stunning, natural-looking restorations with ease.

Firing Table

HeraCeram cre-active 2D / Glaze / Glaze Fluo

| HeraCeram | HeraCeram Saphir |

HeraCeram Sun |

HeraCeram Zirkonia | HeraCeram Zirkonia 750 with lithium disilicate | HeraCeram Zirkonia 750 with zirconium dioxid | 1-4 units: Lithium disilicate, monolithic zirconium dioxide |

4-xx units: monolithic zirconium dioxide |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Start temperature | [°C] | 600 | 600 | 600 | 600 | 400 | 500 | 450 | 450 | |||||

| Drying | [min] | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 8 | |||||

| Pre-heating | [min] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | |||||

| Temperature increase | [°C/min] | 100 | 100 | 100 | 100 | 60 | 60 | 55 | 45 | |||||

| Final temperature | [°C] | 850 | 850 | 740 | 850 | 725 | 725 | 740 | 740 | |||||

| Holding time | [min] | 0,5-1 | 0,5-1 | 0,5-1 | 0,5-1 | 0,5-1 | 0,5-1 | 1 | 1 | |||||

| Vacuum start | [°C] | - | - | - | - | - | --- | 650 | 650 | |||||

| Vacuum stop | [°C] | - | - | - | - | - | --- | 700 | 700 | |||||

HeraCeram cre-active 3D

|

1-4 units: HeraCeram; HeraCeram Saphir; HeraCeramSun; HeraCeram Zirkonia; HeraCeram Zirkonia 750 with lithium disilicate; HeraCeram Zirkonia 750 with zirconium dioxid; lithium disilicate; monolithic zirconium dioxide |

4-xx units: HeraCeram; HeraCeram Saphir; HeraCeramSun; HeraCeram Zirkonia; HeraCeram Zirkonia 750 with zirconium dioxid; monolithic zirconium dioxide |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Start temperature | [°C] | 450 | 450 | |||||||||||

| Drying | [min] | 8 | 10 | |||||||||||

| Pre-heating | [min] | 2 | 5 | |||||||||||

| Temperature increase | [°C/min] | 55 | 30 | |||||||||||

| Final temperature | [°C] | 740 | 740 | |||||||||||

| Holding time | [min] | 1 | 1 | |||||||||||

| Vacuum start | [°C] | 650 | 650 | |||||||||||

| Vacuum stop | [°C] | 730 | 730 | |||||||||||

IMPORTANT NOTICE: The firing temperatures given are intended as guidelines. Deviations are possible due to varying furnace power and may need to be adapted.

COLOUR MAPPING TABLE

| Bleach | A1 | A2 | A3 | A3,5 | A4 | B1 | B2 | B3 | B4 | C1 | C2 | C3 | C4 | D2 | D3 | D4 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2D | Body stains | - |

2D B-A |

2D B-A |

2D B-A | 2D B-A | 2D B-A | 2D B-B | 2D B-B | 2D B-B | 2D B-B | 2D B-C | 2D B-C | 2D B-C | 2D B-C | 2D B-D | 2D B-D | 2D B-D |

| 2D | Mamelon- / or Secondary Dentine |

2D MD1 |

2D MD1 |

2D MD1 |

2D SD2 |

2D SD2 |

2D SD2 |

2D MD2 |

2D MD2 |

2D MD3 |

2D MD3 |

2D MD2 |

2D SD1 |

2D SD2 |

2D SD2 |

2D MD1 |

2D MD3 |

2D SD1 |

| 2D | Value |

2D VL1 |

2D VL1 |

2D VL1 |

2D VL3 |

2D VL3 |

2D VL3 |

2D VL1 |

2D VL1 |

2D VL3 |

2D VL3 |

2D VL1 |

2D VL1 |

2D VL3 |

2D VL3 |

2D VL1 |

2D VL3 |

2D VL3 |

| 3D | Enamel |

3D OS-BL |

3D OS-BL |

3D OS-BL |

3D OS |

3D OS |

3D OS |

3D OS-BL | 3D OS-BL |

3D OS |

3D OS |

3D OS-BL |

3D OS |

3D OS |

3D OS |

3D OS-BL |

3D OS |

3D OS |

| 3D | Body Correction |

3D BC BL |

3D BC-A |

3D BC-A |

3D BC-A |

3D BC-A |

3D BC-A |

3D BC-B |

3D BC-B |

3D BC-B |

3D BC-B |

3D BC-C |

3D BC-C |

3D BC-C |

3D BC-C |

3D BC-D |

3D BC-D |

3D BC-D |

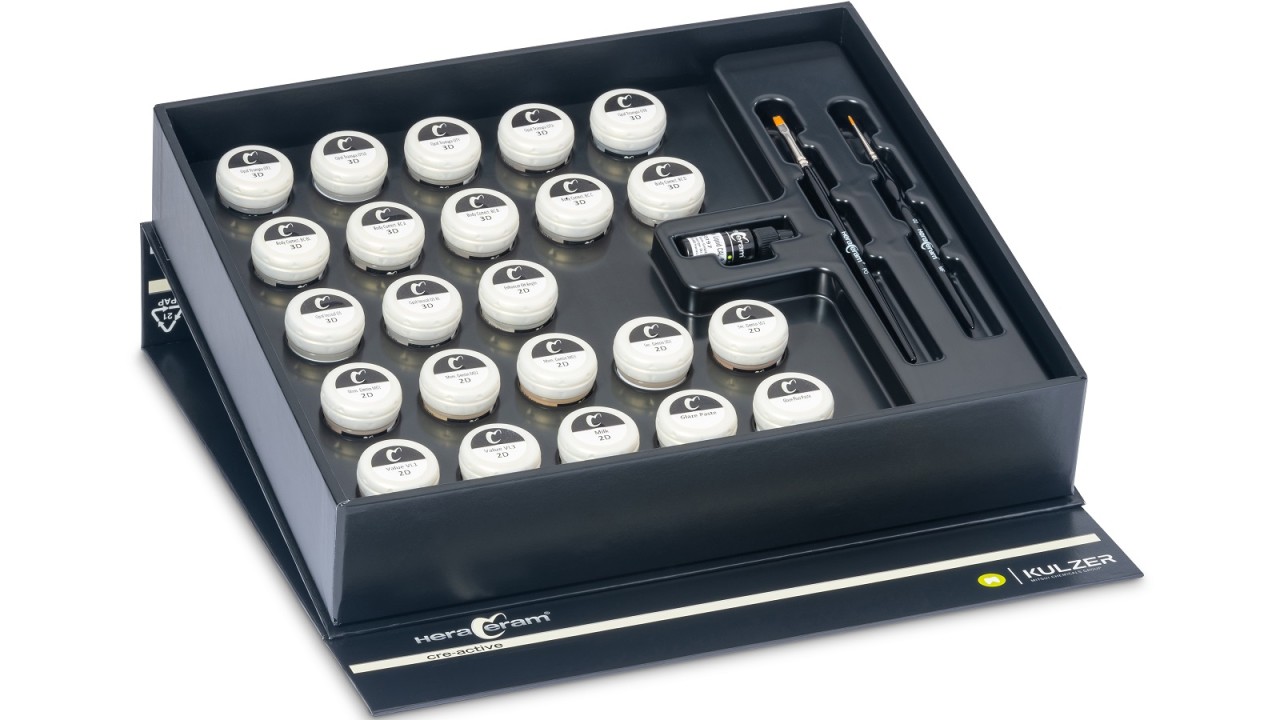

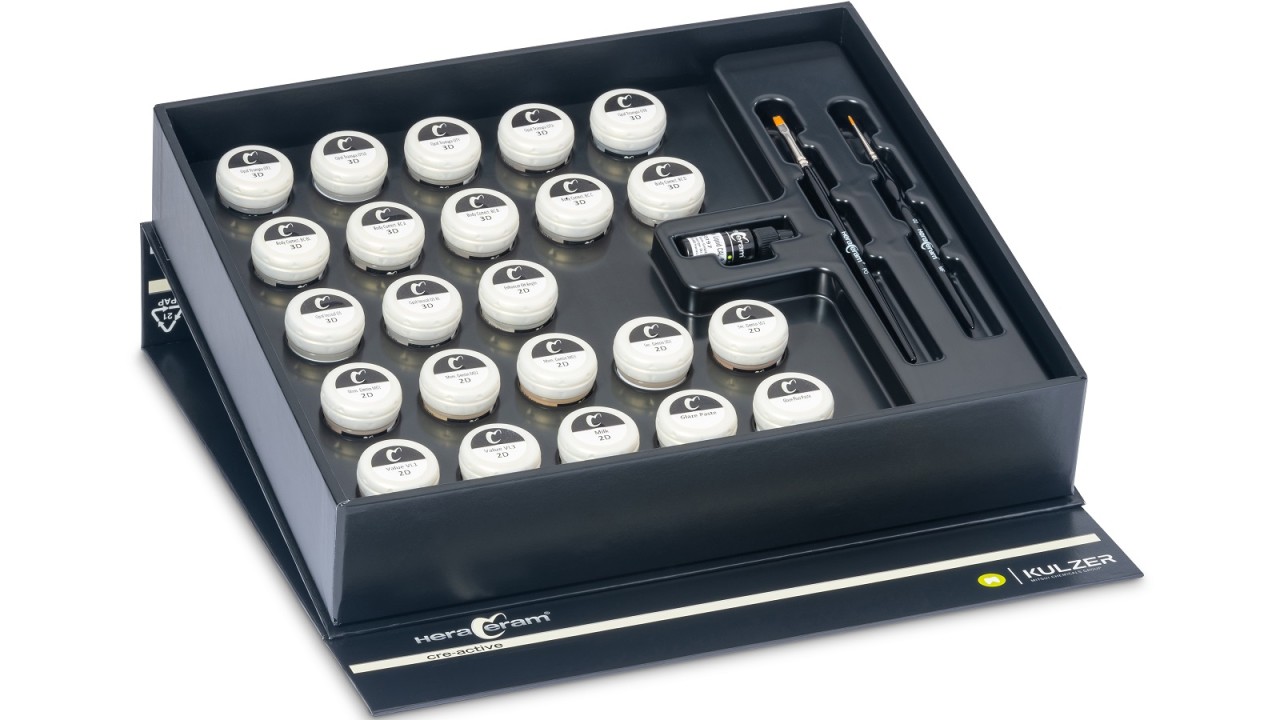

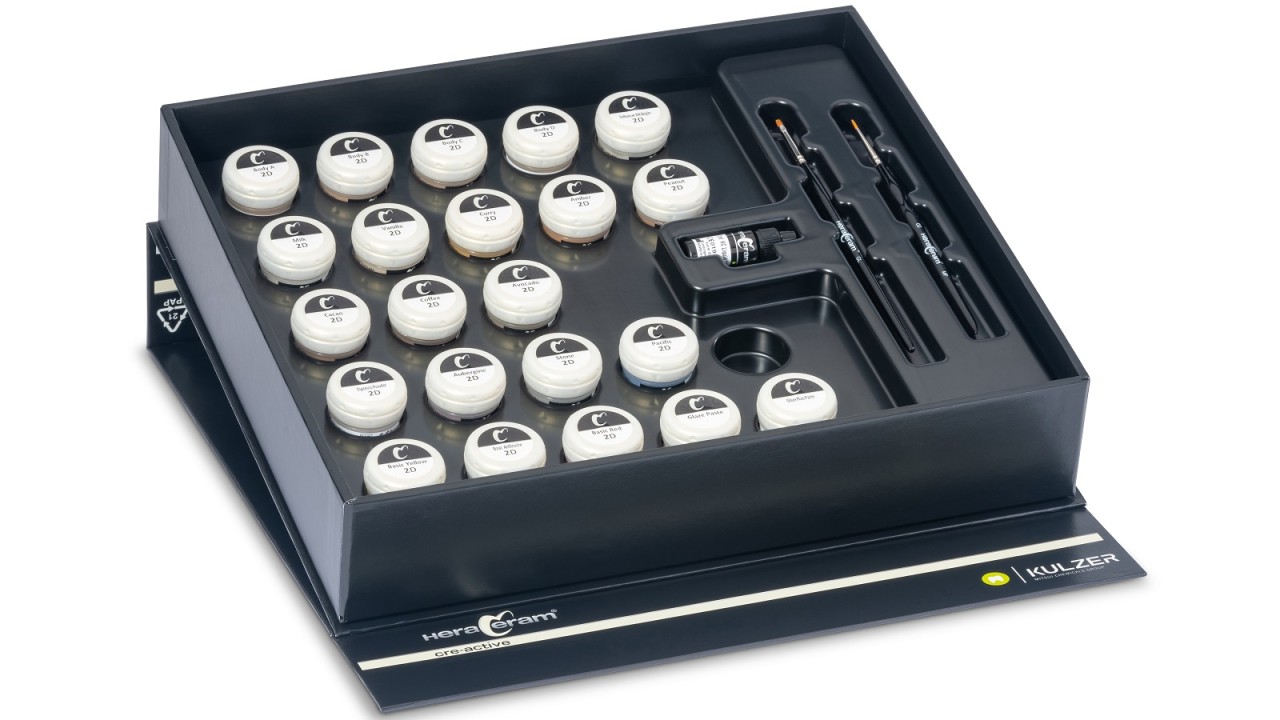

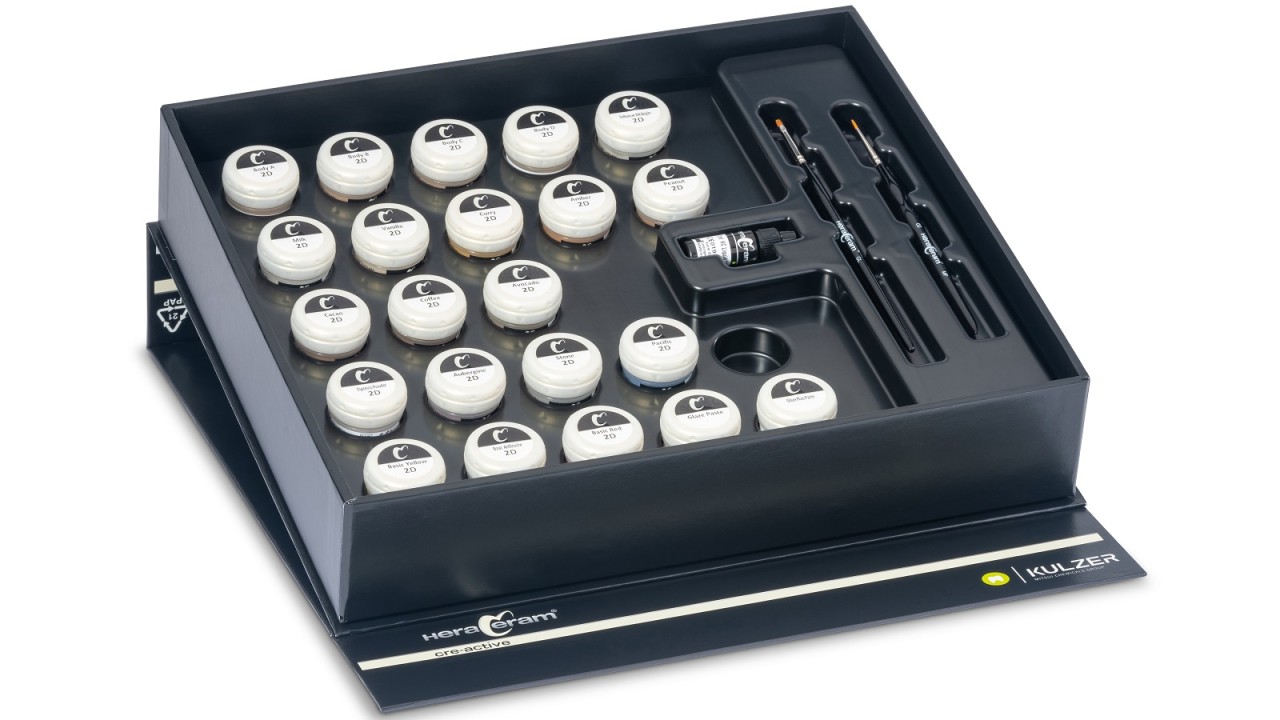

HeraCeram cre-active sets & accessories

Sets

Overview of HeraCeram cre-active sets

HeraCeram cre-active Basic-Set (2D/3D)

➤ Art.-No. 66094145

HeraCeram cre-active Matrix-Set (2D/3D)

➤ Art.-No. 66094146

HeraCeram cre-active 2D Stains/Glaze-Set (2D)

➤ Art.-No. 66094147

HeraCeram cre-active Gingiva-Set (2D/3D)

➤ Art.-No. 66094148

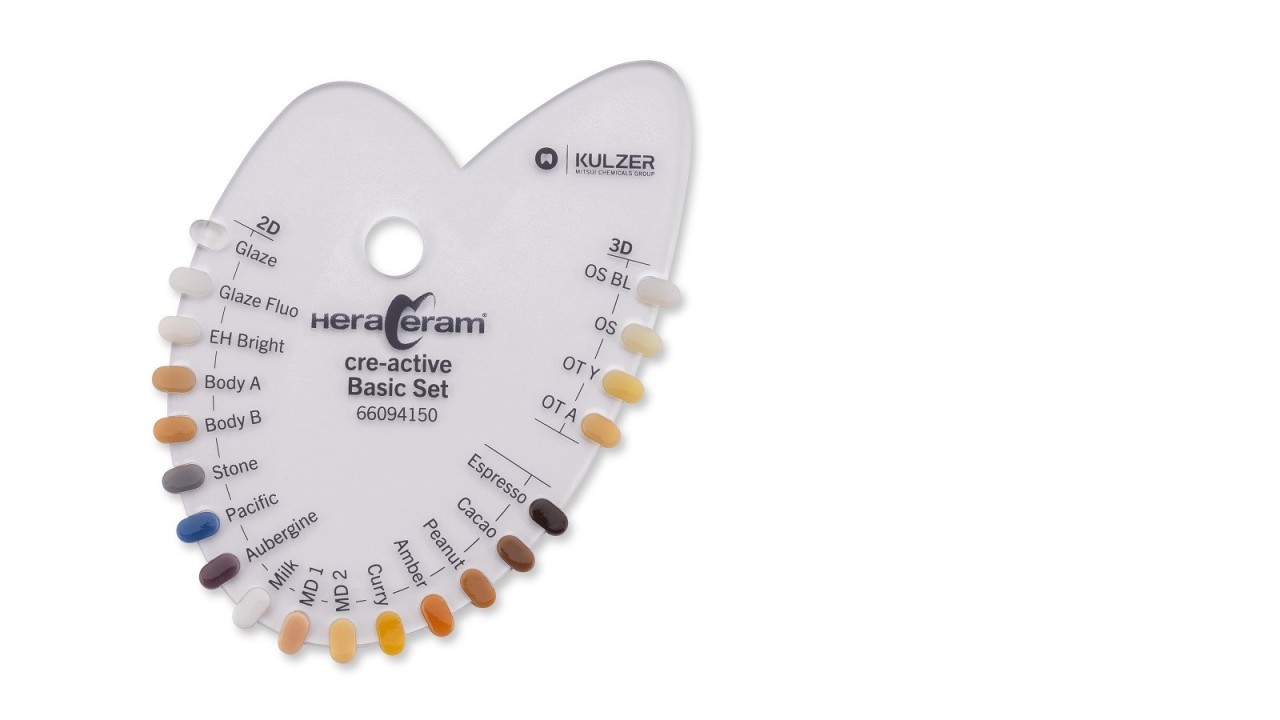

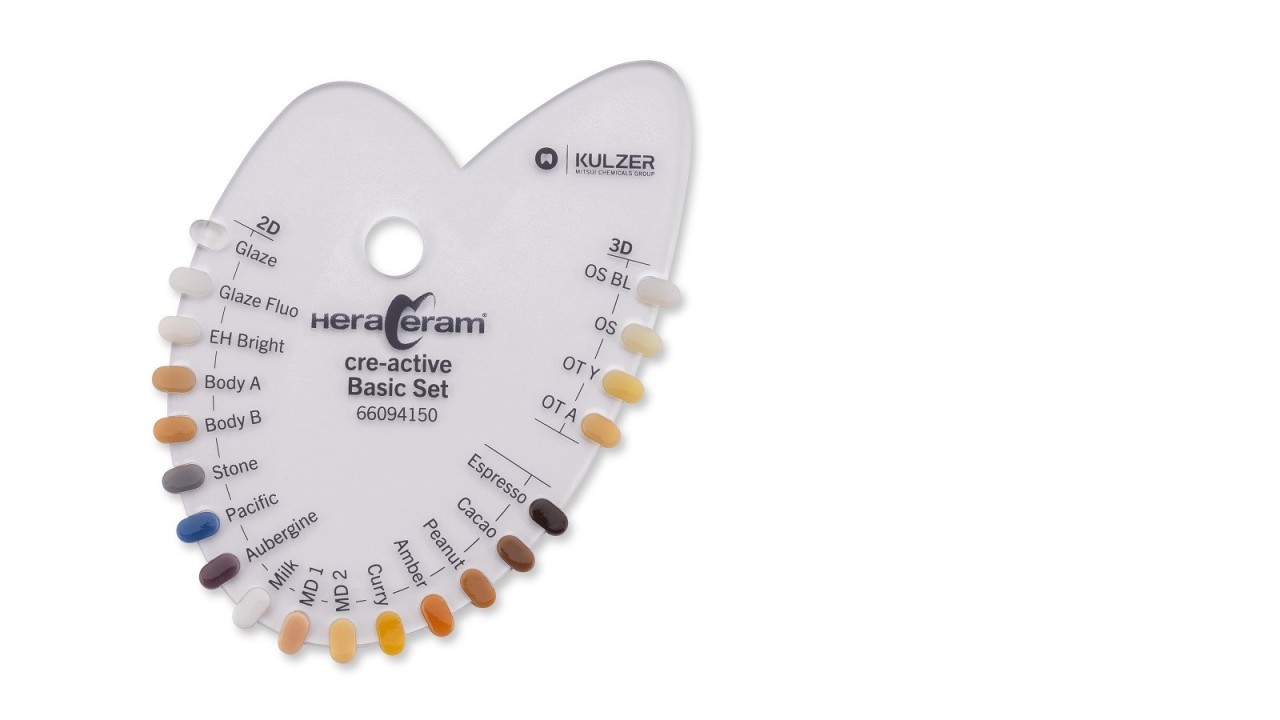

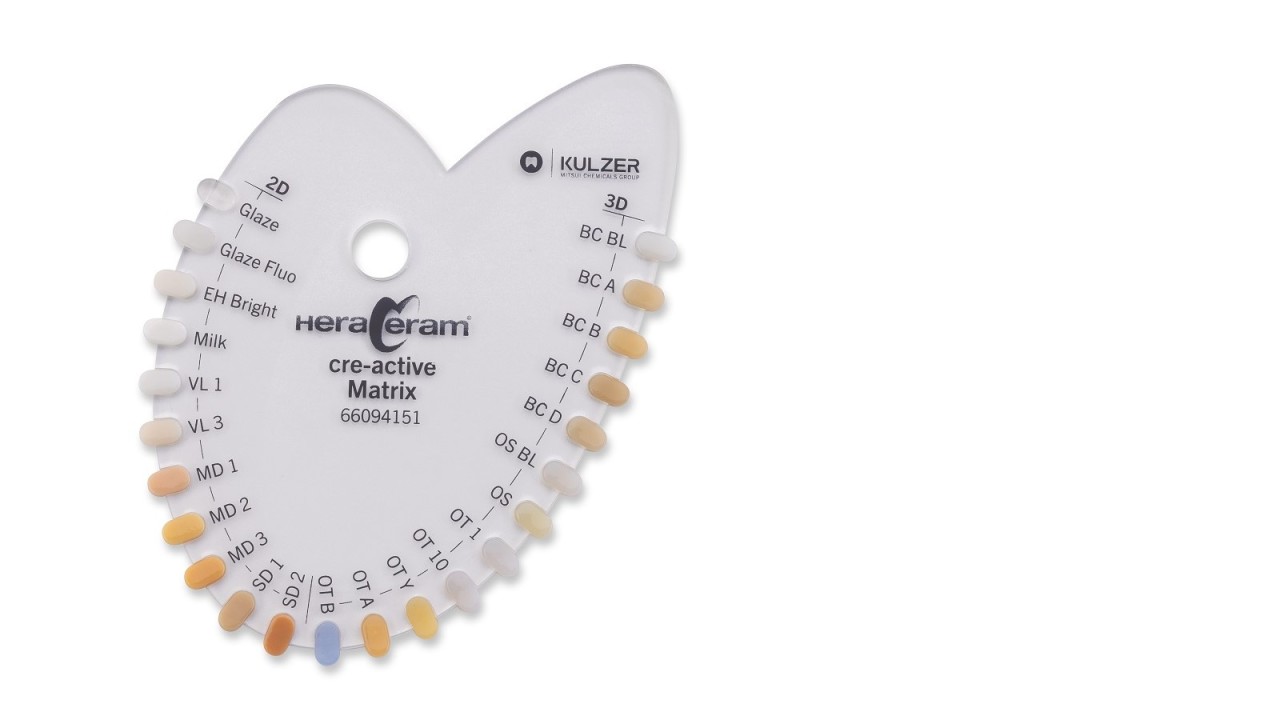

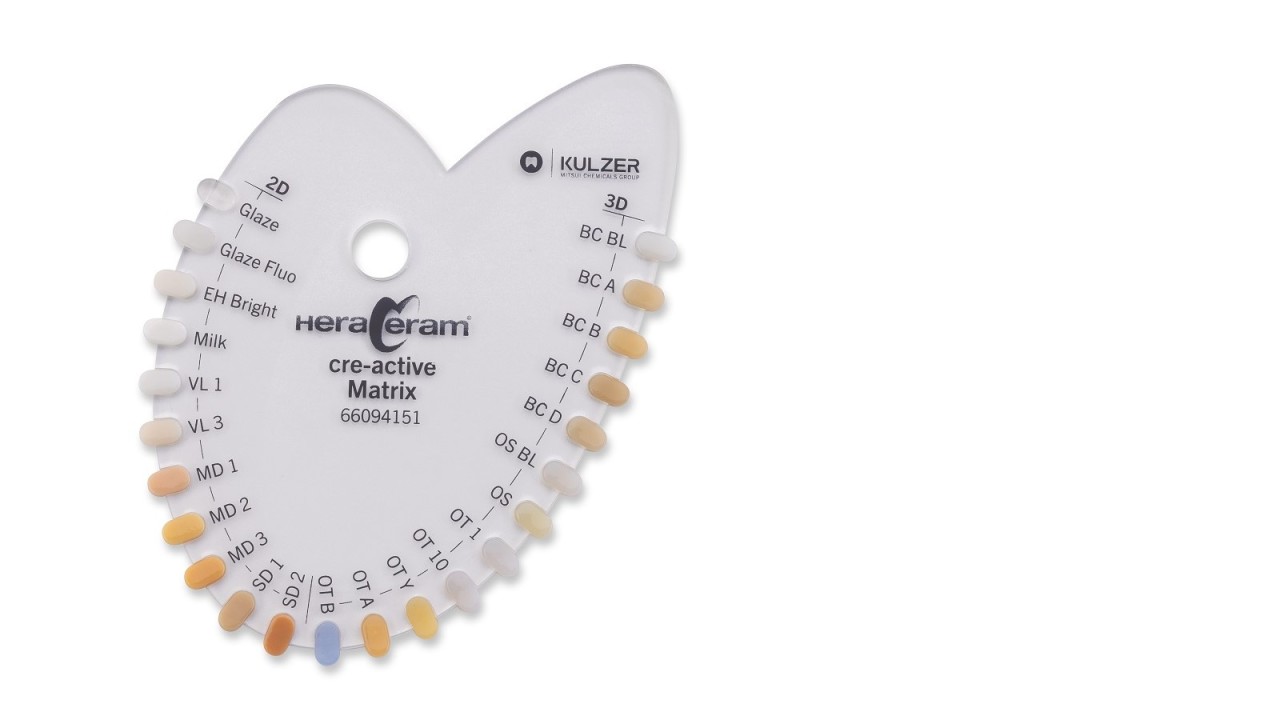

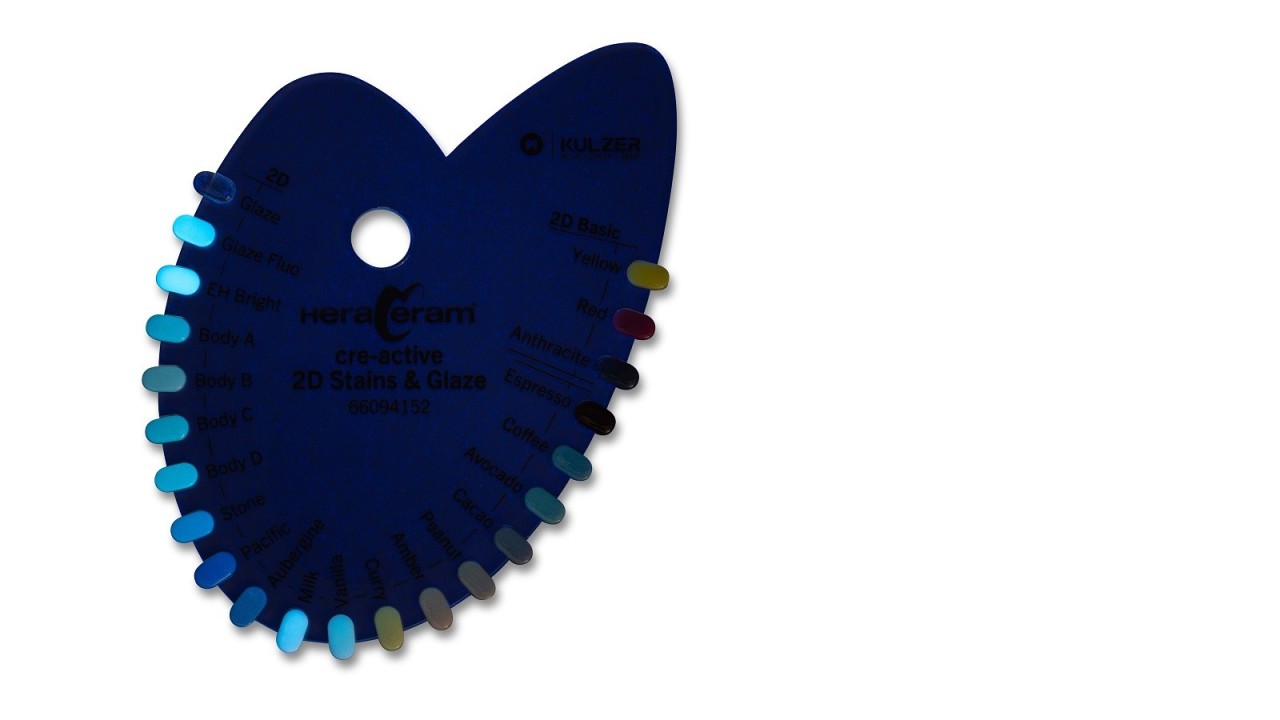

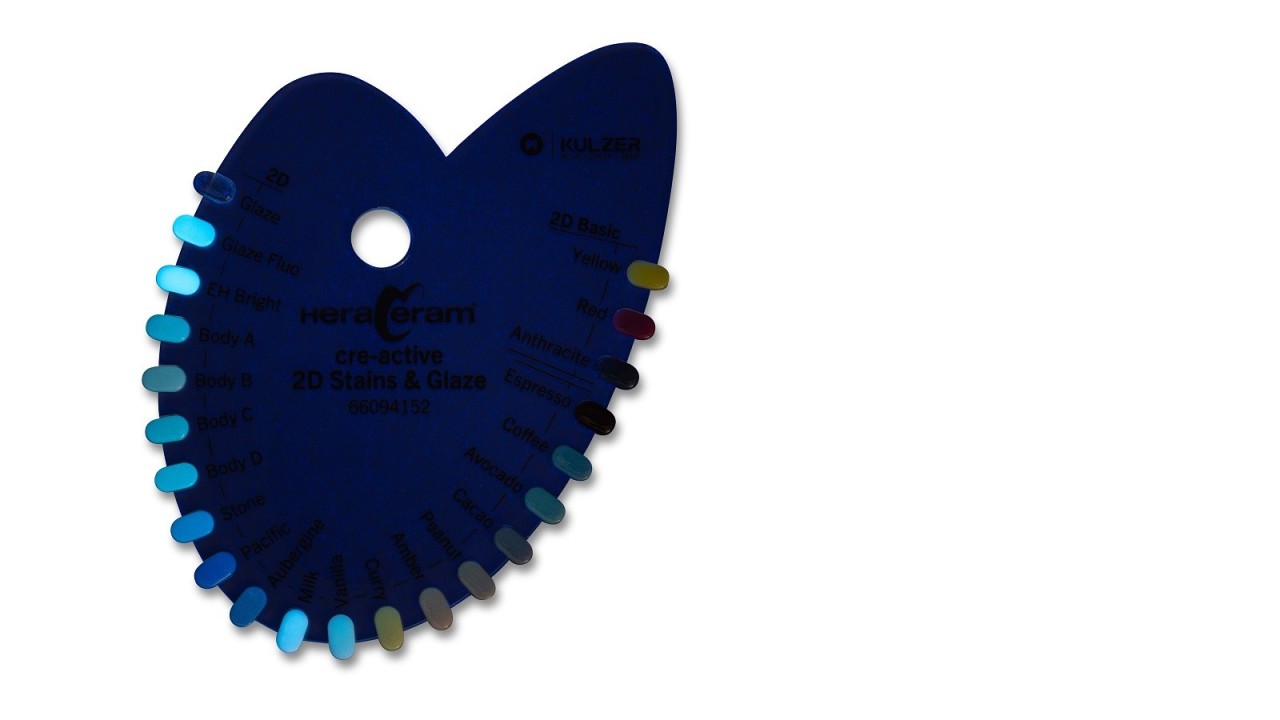

Shade Guides

Appropriate preview of the colour results: Our shade guides are made from the original ceramics and show the expected colour.

HeraCeram cre-active Shade Guide Basic-Set

➤ Art.-No. 66094150

HeraCeram cre-active Shade Guide Matrix

➤ Art.-No. 66094151

HeraCeram cre-active Shade Guide 2D Stains

➤ Art.-No. 66094152

HeraCeram cre-active Shade Guide Gingiva

➤ Art.-No. 66094154

Brushes

The right tool is a prerequisite for ergonomic work. Our brushes are matched to the respective processing steps.

Glaze material & Liquid

Glaze material

- HeraCeram cre-active Glaze Paste, 3ml ➤ 66094096

- HeraCeram cre-active Glaze Fluo Paste, 3ml ➤ 66094097

- HeraCeram cre-active Glaze Powder, 15 g ➤ 66094155

- HeraCeram cre-active Glaze Fluo Powder, 15g ➤ 66094156

Liquid

Only one liquid for mixing, diluiting and re-freshing

- HeraCeram cre-active Liquid CAL, 2 ml ➤ Art.-No. 66094158

- HeraCeram cre-active Liquid CAL, 20 ml ➤ Art.-No. 66094159

FAQ

Product properties

| HeraCeram cre-active 2D / Glaze / Glaze Fluo | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CTE (25-400°) | 9,0 ± 0,3 μm/m・K | |||||||||||||

| CTE (25-500°) | not available | |||||||||||||

| TG | 490° ± 20°C | |||||||||||||

| HeraCeram cre-active 3D | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CTE (25-400°) | 9,2 ± 0,3 μm/m・K | |||||||||||||

| CTE (25-500°) | not available | |||||||||||||

| TG | 490° ± 20°C | |||||||||||||

Product consistency

Mixing before use

Stear HeraCeram cre-active 2D, 3D or Glaze / Glaze Fluo (paste) components well with a metal-free spatula before each use! Due to their ceramic base, the pasts can sediment from the liquid. Do not pour surplus liquid out of the container. Mix it back into a paste. The pastes become softer with movement and easy to work with.

Consistency adjustment

The consistency of the material may vary depending on the room temperature.

The consistency of the HeraCeram cre-active 2D and 3D pastes can be individually adjusted by carefully adding HeraCeram cre-active Liquid (CAL) or HeraCeram cre-active Glaze / Glaze Fluo (paste) components.

Prolonged storage

If the consistency of the HeraCeram cre-active 2D or 3D pastes or HeraCeram cre-active Glaze / Glaze Fluo pastes becomes drier and thus firmer due to prolonged storage, the viscosity can be readjusted by carefully adding the HeraCeram cre-active Liquid (CAL).

Liquid

Which to use

HeraCeram cre-active Liquid (CAL) must be used. The use of staining liquids or thinner liquids on ceramic lines manufactured by competitors is not indicated.

How to use

The consistency of the HeraCeram cre-active 2D and 3D pastes can be individually adjusted by carefully adding HeraCeram cre-active Liquid (CAL) or HeraCeram cre-active Glaze / Glaze Fluo (paste) components.

Product Application

Surface preparation

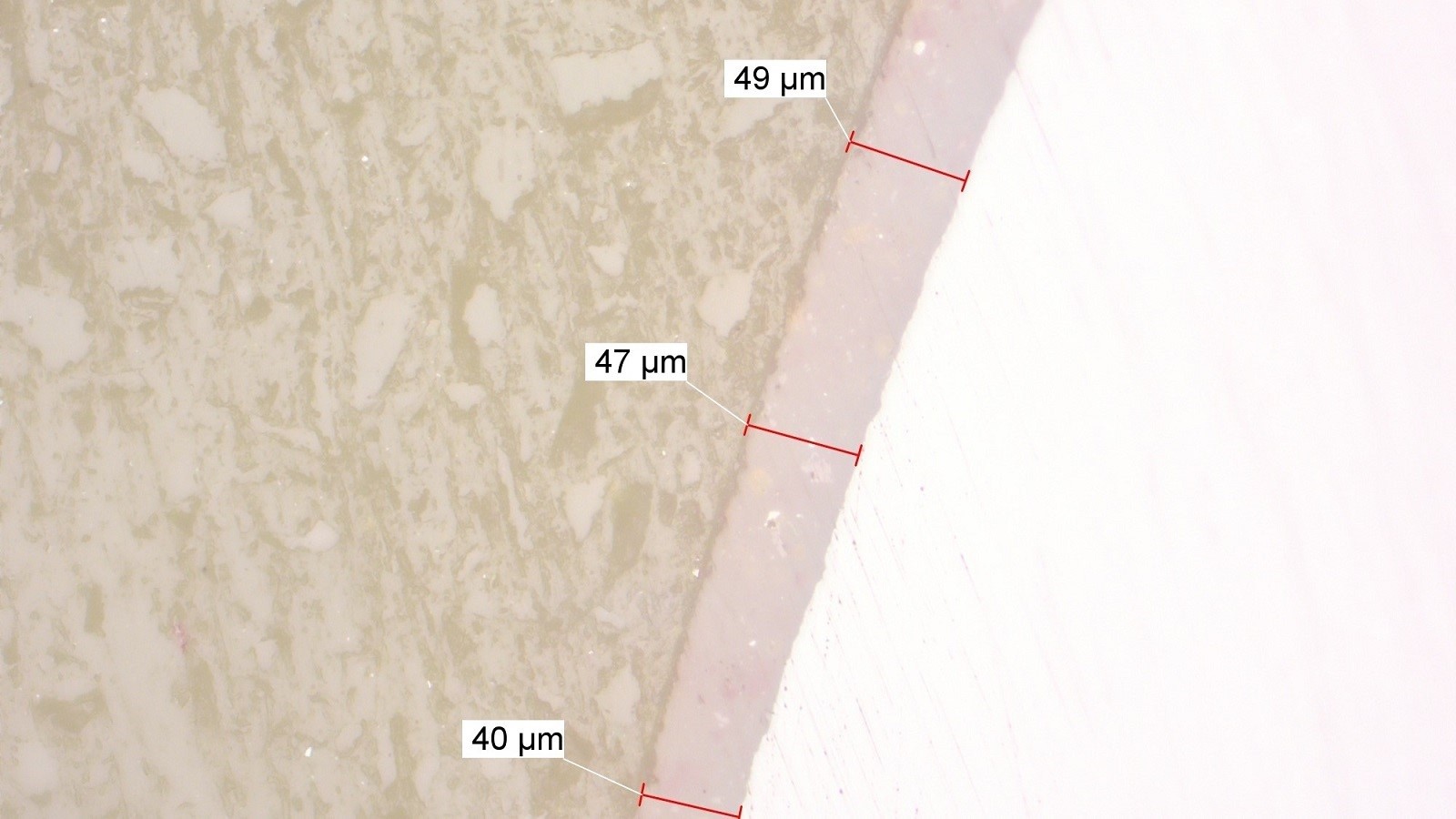

The surface of the restoration for customisation must be developed, i.e. contours and surface structures must be designed using diamond abrasives or indicated rotating instruments. Prepare the zirconium dioxide after milling resp. Lithium Disilicate frameworks after milling or pressing in acc. to the manufacturer‘s Instructions for Use. Unless otherwise specified in manufacturer's Instruction for Use treat zirconium dioxide with 110 – 125 μm and Lithum Disilicate using 50 μm disposable blasting corundum (Al₂O₃).The recommended jet pressure is 2 bar. Afterwards, remove any grinding dust and impurities from the surface, e.g. with a steam jet.

Layer thickness

HeraCeram cre-active 3D components can be applied in a layer thickness of 0.1 – 0.3 mm over the individually stained or glazed surface. For a layer thicknesses over 0.3 mm on zirconium dioxide or lithium disilicate, the layering ceramic indicated for the respective framework material should be used (e.g. HeraCeram Zirkonia 750)!

Application of HeraCeram cre-active 2D / Glaze / Glaze Fluo components

The fully developed restoration can be individually characterised using various HeraCeram cre-active Glaze / Glaze Fluo and HeraCeram cre-active 2D masses. The components can be combined/ mixed individually with each other. Stear all paste compounds well with a metal-free spatula before each use. Due to their ceramic base, pasty masses can sediment from the liquid. HeraCeram cre-active 2D Espresso as well as HeraCeram cre-active Glaze and Glaze Fluo components are available in powder form. To prepare the ready-to-use powder masses, the ceramic powders are mixed with HeraCeram cre-active Liquid (CAL). Wetting the ceramic surface with HeraCeram cre-active Liquid (CAL) makes the layering and colour impression more visible.

Application of HeraCeram cre-active 3D components

Before applying the HeraCeram cre-active 3D components, the surface must already be wetted and fired with a layer of HeraCeram cre-active 2D or HeraCeram cre-active Glaze / Glaze Fluo compound. On zirconium dioxide or lithium disilicate framework surfaces alternatively HeraCeram Zirkonia 750 Adhesive can be applied with a brush in an evenly thin layer (wash) and fired under vacuum (see firing chart in HeraCeram Zirkonia 750 instructions for use). Stear HeraCeram cre-active 3D components well with a metal-free spatula before each use. Due to their ceramic base, pasty masses can sediment from the liquid. Afterwards apply the desired HeraCeram cre-active 3D mass and model it into the desired shape with a clean brush. The components can be combined/ mixed individually with each other. The consistency of the HeraCeram cre-active 3D pastes can be individually adjusted by carefully adding HeraCeram cre-active Liquid (CAL) or HeraCeram cre-active Glaze / Glaze Fluo components. The optimum layer thickness of the HeraCeram cre-active 3D materials are 0.1 to max. 0.3 mm.

Firing Procedure

The degree of glazing and the texture of the ceramic surface are defined during firing by the temperature and the holding time. For this reason, the specifications for the firing temperature and holding time are for orientation only and may need to be adjusted to achieve the required result. Firing procedure see general firing tables.

Working environment

Avoid impurities

Pay attention to the cleanliness of the brushes, metal-free spatula and working environment. Any contamination from the outside can have a negative influence to the aesthetic result after firing. Danger of impurities!

Storage

Storage conditions

Carefully reseal the container after removing the product to avoid contamination, clumping and drying out. No special storage conditions required.

Prolonged storage

If the consistency of the HeraCeram cre-active 2D or 3D pastes or HeraCeram cre-active Glaze / Glaze Fluo pastes becomes drier and thus firmer due to prolonged storage, the viscosity can be readjusted by carefully adding the HeraCeram cre-active Liquid (CAL).

Downloads

Contact