Contact Kulzer International

Hera® SG - for C&B

Reduced precious metal dental casting alloy acc. to EN ISO 22674, yellow

Benefits

- Entire crown and bridge indication range and milling

- Many years of user experience

Indications

- Inlays

- MOD inlays

- Crowns

- Bridges

- Milling procedures

- Cast partial denture

- Cast posts

- Implants

Specifications

| Product details | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Composition (content in mass %) |

Au 55.6 Ag 24.4 Pt 1.0 Pd 3.7 Cu 14.0 Zn 1.0 In 0.2 Ir x Ru x |

|||||||||||||

| Type | 4 (w/v) | |||||||||||||

| Shade | Yellow | |||||||||||||

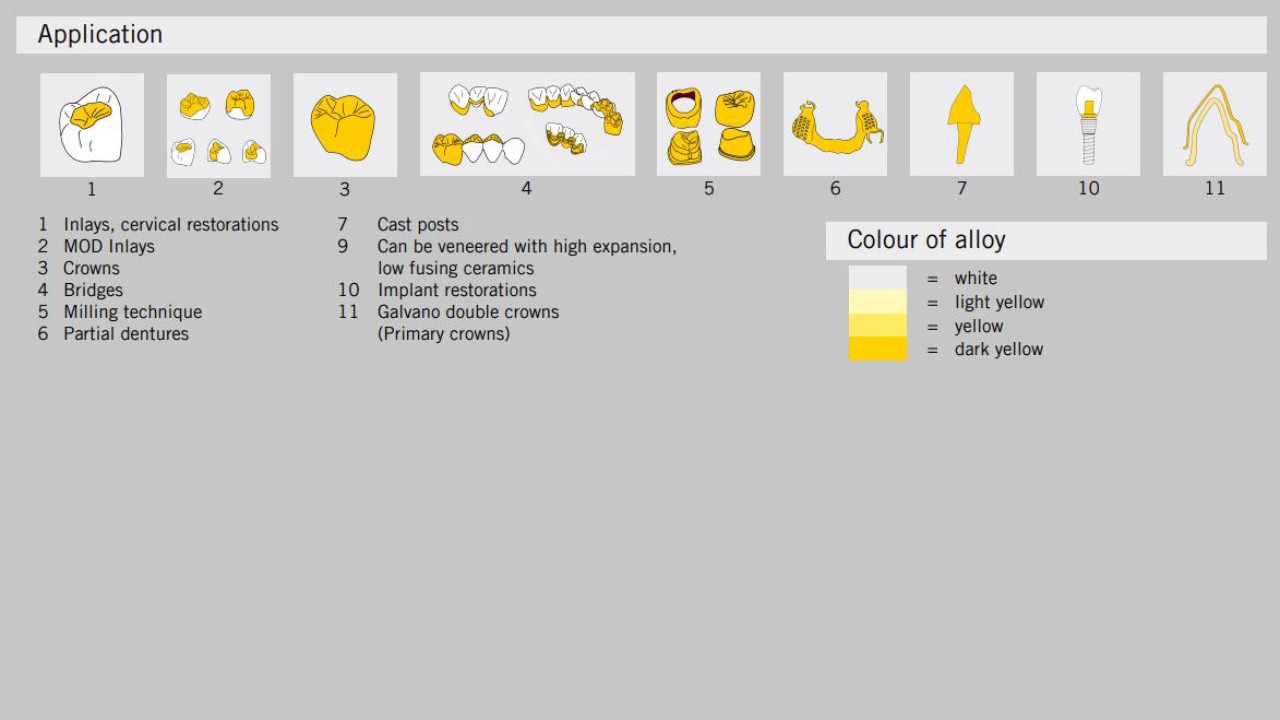

| Indication |

Inlays, cervical restorations MOD Inlays Crowns Bridges Milling technique Partial dentures Cast posts Implant restorations |

|||||||||||||

| Article Code | 15500000 | |||||||||||||

| Technical data melting and casting | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Melting range (1) |

Solidus 840°C Liquidus 895°C |

|||||||||||||

| Preheating temperature | 700°C | |||||||||||||

| Casting temperature | 1000°C | |||||||||||||

| Crucible | Graphite | |||||||||||||

| Density (1) | 13.7 g/cm3 | |||||||||||||

| Hardness, HV5 | 195 (w/k), 280 (v), 280 (s) | |||||||||||||

| 0.2 % proof stress(1), MPa(2) | 530 (w/k), 860 (v) | |||||||||||||

| Elongation(1) % | 25 (w/k), 5 (v) | |||||||||||||

| Elastic modulus(1), GPa(2) | 100 | |||||||||||||

| Ceramic firing | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CTE | --- | |||||||||||||

| Oxide firing | --- | |||||||||||||

| Soft annealing | 750°C /15 min. | |||||||||||||

| Processing after oxide firing | --- | |||||||||||||

| Cooling after ceramic firing (Relexation cooling is recommended for lang span, bulky frameworks) | --- | |||||||||||||

| Hardening | 400°C / 15 min. | |||||||||||||

| Prior to Ceramic Firing | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solder |

Hera Lot 800 + Maingold / Hera Lot 750 |

|||||||||||||

| Solder colour: yellow | ||||||||||||||

| After Ceramic Firing | ||||||||||||||

| Solder | Hera Lot 800 + Maingold / Hera Lot 750 | |||||||||||||

| Flux** | Solder colour: yellow | |||||||||||||

|

Alloy not available as Laser welding wire Recommended alternative alloy Laser welding wire: Hera GG(2) |

||||||||||||||

Specification legend

Composition:

w = After soft annealing and quenching

k = Bonding alloy: condition after ceramic firing

v = Condition after hardening

s = Self-hardening alloy, after slow cooling in the mould

Remarks

A = A stable framework design with reinforced connections with a cross-section of 8 –10 mm2 is required for long span bridges and suprastructures. Additionally, the frameworks need to be hardened.

B = Depending on the copper and/or silver content, in some cases discoloration of double crowns may result after short period of wearing.

C = In exceptional cases these alloys can also be used for traditional telescopic crowns with parallel walls and for the bar casting technique provided that cross-sections for crown walls, approximal areas, bars and laser welded joints are particularly thick and the alloy is hardened subsequently. No indication for conical crowns and shear distributors.

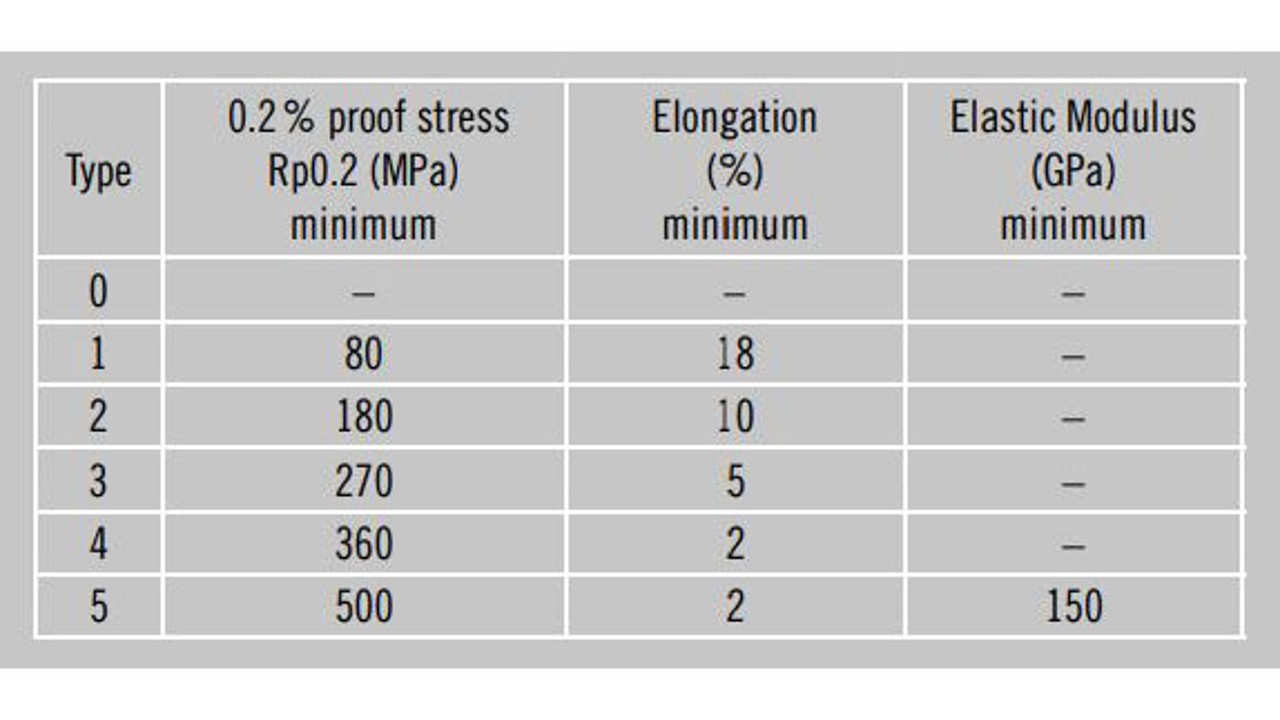

D = Type classification acc. EN ISO 22674

Technical Data, Melting and Casting:

Contraindications

In case of hypersensitivity (allergies) to one of the constituents of the alloy.

Side effects

In individual cases hypersensitivity reactions (allergies) or electrochemically conditioned, local malsensations were reported.

Interactions with other dental alloys

With approximal or antagonist contact with dentures of different alloys galvanic effects may occur. Other materials must be used instead if contact with other alloys causes persistent local paraesthesia on an electrochemical basis.

1) Acc. to EN ISO 22674

2) 1MPa = 1N/mm², 1GPa = 1000 N/mm²

3) When veneered with ceramics, these alloys do not require any additional hardening process to provide their max. physical values.

4) Normally, the pre-heating temperature shall be 900 °C. In case of form filling problems with thin copings we recommend to raise the pre-heating temperature to 950 °C.

5) For cast-on technique

Ceramic Firing:

Remarks

1) When veneering with ceramics with higher firing temperature, oxide firing must be carried out at the highest ceramic firing temperature; max. temperature of 950 °C must not be exceeded.

2) Oxide firing: Please follow the instructions of the ceramic manufacturer.

3) Follow the instructions of the ceramic manufacturer.

4) Hardening prior to firing (conditioning for milling techniques): 930 °C, 15min, rapid cooling.

5) When veneered with ceramics, these alloys do not require any additional hardening process to provide their maximum physical values.

6) 25 – 500 °C acc. EN ISO 9693

Solders / Laser Welding Wires:

Remarks

* The working temperature is part of the solder’s name.

** Recommended flux:

Precious metal/ precious metal: use suitable flux

Precious metal/ non precious metal: use suitable flux

Non precious metal/ non precious metal: use suitable flux

1) Herador Lot V800 must be soldered under vacuum. Graphite firing trays should be used.

2) Recommended alternative alloy.

3) When processed with HeraCeram.

5) Accurate temperature control must be ensured. 740 °C must not be exceeded. Maximum heat-rate: 55 °C/min.