Contact Kulzer International

What connects aerospace and dental excellence?

Find out how Dr Christoph Meier of Kulzer applies lessons from aerospace and other industries to develop innovative dental materials. How does he and his team leverage cross-industry expertise and company synergies to bring advanced dental solutions to market?

There’s no way around it: Developing innovative dental materials is expensive, especially the kind of which Kulzer’s Christoph Meier dreams. “This is a big difference to other industries,” he says, “in which you often have to deal with strict limitations of costs and cannot start being so creative in terms of new chemical solutions.” Too much is at stake to cut corners during any stage of the process. Under his watch, Kulzer leverages corporate synergies and economies of scale to do ambitious R&D, yet still bring products to market that deliver great value. How?

By applying lessons from other industries. Meier is a specialist in polymer-based composite materials. “At Airbus, I developed high-temperature carbon-fiber reinforced composites, and at Hilti, two-component fire protection coatings. The chemical background is similar, so the transfer between these fields is ‘only’ the final application.” Polymer-based composites, he explains, always follow the same principle: The final composite is a mixture of a polymer-based matrix and other ingredients, which exhibit different properties than the single substances.

Another thing you can do is lean on your connections. In this case, Meier doesn’t have to look far. His team regularly collaborates with other R&D professionals from shareholder Mitsui Chemical’s extensive network of companies in electronics, automotive and other fields. “Together, we try to find synergies inside Mitsui, develop custom-made chemical solutions and try to transfer them to the dental field,” he says. Because discoveries at one entity often fuel advances at another, there’s a genuine esprit de corps among researchers, which has resulted in several patents, plus cost savings that can be passed on to consumers.

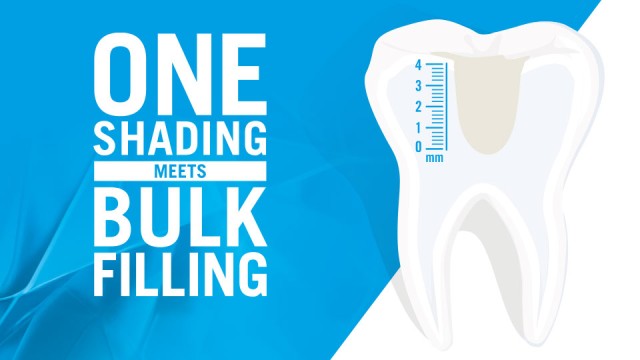

Meier’s work centers on developing new technologies, whether raw materials, devices or processes—“technology platforms that can be used for several product variations.” Consider his involvement in the ONE line of single-shade composite materials. Not only are they a clinical success, but they satisfy Meier’s directive that these platforms contribute to simplification for practitioners. “I’m especially proud of the new flowable Venus Bulk Flow ONE,” which he says “shows a significant advantage by combining the exceptional ONE-shade effect with bulk-filling properties—curing depth of at least four millimeters—without the need for an additional capping layer.”

| “We’re always looking into new technological fields that do not yet fit certain product strategies. There is no fixed time frame for these, but they are necessary to find creative new solutions.” |

| Dr Christoph Meier, Head of R&D Technology Development |

There are, inescapably, a lot of steps involved. As such, product development times vary wildly. There’s prototyping, careful evaluation, market analysis and product viability vetting, plus customer feedback from their dental advisory boards before a new process is greenlit. Even that summary is a vast oversimplification: It doesn’t include regulatory hurdles, which Meier says make things increasingly complex, like Europe’s recent transition from MDD (Medical Device Directive) to MDR (Medical Device Regulation), which is far broader in scope. And that’s just Europe.

Meier remains passionate about chemistry and materials, able to talk for hours about one advance after another, like Kulzer’s unique Tricyclodecane (TCD) matrix used in the Venus Diamond/Pearl ONE composites. “[The] molecules vibrate less and take up less space than traditional matrix molecules. Minimal movement results in significant benefits such as low shrinkage stress, which reduces the risk of marginal gap formation and secondary caries. In addition, the high level of cross-linking in the TCD matrix increases the strength and durability of the composite.” Still, the teamwork, the processes and the birthing of new products brings out the people-pleaser in him. It’s a “great joy,” he says, especially “when [we] push new technologies that could solve unknown pain points. Seeing ideas accepted by customers is great motivation.”

This article was first published in the Spring 2024 issue of Benco Dental's Incisal Edge.

Leave a comment

-

Manager Corporate Communications

-

Matthias Brehmke

- More blog posts